In the world of specialty coffee, consistency is the ultimate pursuit. For a head barista or a roasting brand owner, variables like grind size, water temperature, and agitation are meticulously controlled. However, one variable is often overlooked: The physical properties of the filter paper itself.

At Deer Coffee Filter, we don’t just manufacture paper; we engineer extraction tools. Today, we delve into the physics of paper thickness (Grammage) and how it dictates the flow rate of a V60 brew.

1. The Physics of Porosity and Thickness

The thickness of a V60 filter is typically measured in GSM (Grams per Square Meter). This measurement is a proxy for the fiber density of the paper.

- Thin Paper (Low GSM): Typically allows for faster flow. The shorter path for water to travel means less contact time, resulting in a brew with high clarity and emphasized acidity.

- Thick Paper (High GSM): Creates a deeper “filtration bed.” As water passes through more layers of cellulose fibers, it encounters more resistance. This increases contact time, which can enhance body and sweetness but risks over-extraction if not managed.

2. The “Clogging” Factor: Beyond Just Thickness

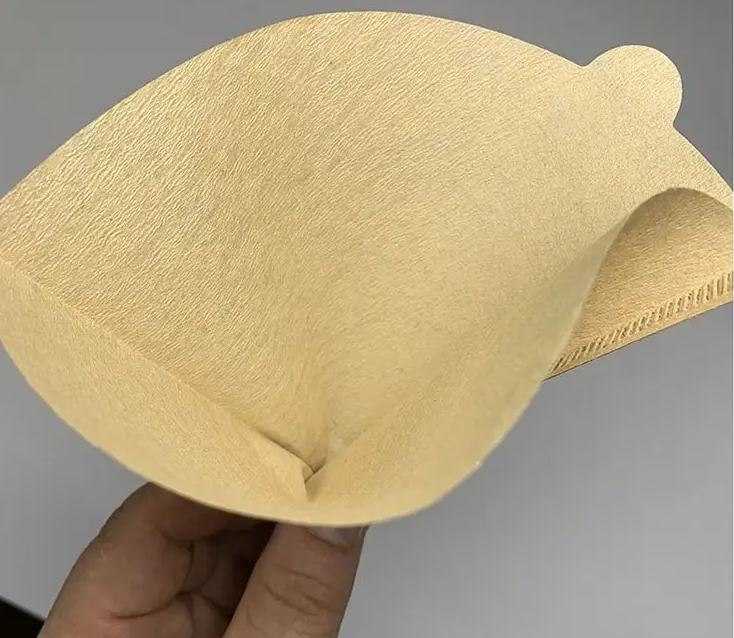

Thickness alone doesn’t tell the whole story. The Creping (the textured ridges) on the surface of the paper plays a vital role.

High-quality V60 filters, like those produced by Deer Coffee Filter, feature a dual-sided creping process. This texture keeps a microscopic gap between the paper and the dripper wall, preventing “vacuum sealing” and ensuring that air can escape.

If a thick paper lacks proper creping, the flow rate will stall (clog), leading to a bitter, astringent cup. Our engineering team optimizes the ratio between Thickness and Crepiness to ensure a steady, linear drawdown.

3. Extraction Flow Rate: A Comparative Test

In our laboratory, we tested the Deer V60 02 Filter against standard industry benchmarks.

| Metric | Deer Precision Series | Standard Economy Filter | Impact on Flavor |

| Avg. Thickness | 0.15mm (±0.01) | 0.12mm (Variable) | Consistent thermal retention |

| Drawdown Time | 2’45” – 3’00” | 2’15” – 3’30” | Predictable extraction cycles |

| Fiber Uniformity | High (Uniform pores) | Low (Uneven density) | Eliminates “channeling” |

4. Why Professional Roasters Should Care

When you sell a bag of beans, you are selling a flavor promise. If your customer uses a cheap, thin, and uneven filter paper, they will not experience the flavor profile you worked so hard to roast.

By partnering with a professional manufacturer like Deer Coffee Filter, you ensure:

- Repeatability: Every batch of filters has the same GSM and flow rate.

- Purity: Our oxygen-bleaching process removes “lignin” (the woody taste) without thinning the paper to a point of fragility.

- Material Integrity: Our filters maintain their structural shape even at 96°C, preventing sagging that disrupts the extraction cone.

Conclusion: Engineering the Perfect Cup

The thickness of your filter paper is the “gatekeeper” of your extraction. At Deer Coffee Filter, we treat paper manufacturing as a science, providing the stability that specialty coffee brands demand.

Whether you require a specific flow rate for a light-roast Geisha or a robust texture for a medium-roast blend, our OEM services can tailor the thickness and porosity to your brand’s specifications.

Experience the precision of Deer Coffee Filter.

0 Comments