The core function of coffee filter paper lies not only in solid-liquid separation but also in its precise molecular sieving of diterpenes.

【Quantitative Analysis: Filter Paper vs. Filter Mesh】 Scientific research shows that unfiltered coffee (such as French press or Turkish coffee) contains high concentrations of cafestol and kahweol.

Retention Efficiency: High-quality cellulose filter paper achieves a retention rate of 95%–99% for cafestol.

Physical Mechanism: The randomly interwoven fiber structure of the filter paper forms a complex pathway with an equivalent pore size of 10–20 μm, effectively capturing tiny lipid droplets suspended in the coffee liquid.

Comparative Data: In contrast, metal filter mesh (with pore sizes typically between 100–200 μm) has almost no physical interception ability for lipids.

[Health Relevance Logic]

Intake: Daily intake of 10mg of caffeol may lead to an 8-10% increase in serum cholesterol within four weeks.

Intervention: Using paper filter extraction that meets SCA (Specialty Coffee Association) standards can reduce the caffeol content in each cup of coffee to below 0.1mg.

For those concerned about cardiovascular health or with high cholesterol, paper filtration is the only brewing compensation method with clinical statistical significance.

[Safety Compliance Standards] Modern medical-grade transoxidative filtration (TCF) filter paper exhibits near-zero dioxin migration during extraction (Detection Limit < 1ppt), significantly superior to traditional processes, ensuring extremely high food safety standards.

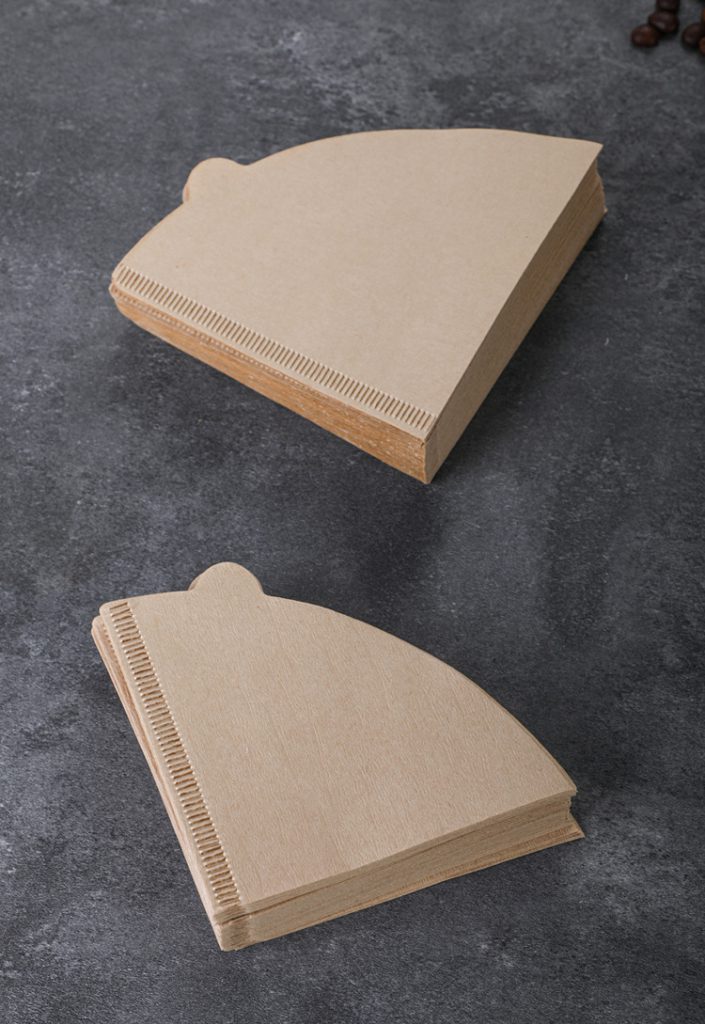

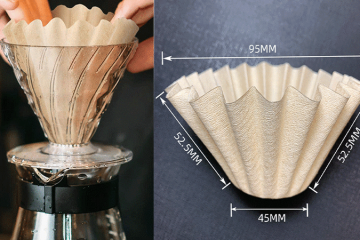

Coffee filter paper is a depth filtration medium. Its microstructure is not a regular grid, but rather a three-dimensional maze composed of randomly interwoven plant fibers. Therefore, its filtration precision cannot be simply equated to the “mesh count” of a single-layer metal mesh, but should be calculated using nominal pore size.

[Quantitative Conversion Model] Average Pore Size: The effective pore size of common specialty coffee filters (such as V60 and Kalita) ranges from 10 μm to 30 μm.

Equivalent Mesh Size Conversion: According to the standard sieve conversion formula, pore size is inversely proportional to mesh size.

20 μm corresponds to approximately 635 mesh (Taylor standard);

15 μm corresponds to approximately 800 mesh;

10 μm corresponds to approximately 1250 mesh.

The physical filtration capacity of coffee filters is equivalent to an ultrafine metal sieve of 600 to 1200 mesh. This explains why even invisible “coffee fines” can be perfectly intercepted by filters, while ordinary metal sieves (approximately 200 mesh) will cause sediment to appear at the bottom of the cup.

[Fluid Dynamics Relationship]

Tortuosity: The tortuosity of the internal path of the filter paper determines the extraction resistance. When water flows through the filter paper, the flow rate is governed by Darcy’s Law, and its permeability $k$ depends on the fiber density.

Dynamic Clogging Effect: During the brewing process, due to the extremely small pore size of the filter paper, very fine particles quickly fill the gaps between the fibers, causing a dynamic increase in the “equivalent mesh size,” resulting in “clogging.” This is why the quality of the filter paper directly affects the flow rate in the latter half of the brewing process.

0 Comments