For baristas who strive for the ultimate flavor, “wetting the filter paper” isn’t a simple “yes” or “no” question, but rather a professional management of variables based on the thermodynamics of the equipment and the fiber properties.

- Thermodynamic Perspective: Filter Cup “Heat Absorption” Compensation

Most people wet the filter paper to “wash away the paper taste,” but from a professional perspective, preheating the filter cup is the core purpose.

Physical Effects: Filter cups (especially those made of ceramic, glass, or metal) have a high heat capacity. If extracted directly, the filter cup will quickly absorb the energy of the hot water, causing a sharp drop in the actual extraction temperature, resulting in a sour, astringent, and under-extracted taste.

Deer’s Recommendation: * If you are using a ceramic or glass filter cup, you must wet it with plenty of hot water and preheat it thoroughly;

If you are using a resin (plastic) filter cup, due to its low thermal conductivity and good insulation, the main purpose of wetting is to ensure fiber adhesion.

- Fluid Dynamics Perspective: The “Breathing Space” Between Filter Paper and Filter Cup

Wetting is not just about soaking; it’s about establishing a tension balance between the filter paper and the filter cup ribs.

Physical Effect: Wetted filter paper adheres tightly to the filter cup ribs due to the surface tension of water. Improper wetting (e.g., localized air bubbles) can obstruct airflow, creating a “bypassing effect,” allowing water to bypass the coffee grounds and flow directly out.

Deer’s Recommendation: When wetting, pour water from the center outwards in a circular motion to ensure the filter paper is flat and adhered to the surface. This ensures smooth carbon dioxide release during extraction, improving the cleanliness of the cupping.

- Fiber Physics Perspective: The “Low Residue” Revolution in Modern Filter Paper

Addressing the traditional pain point of “paper taste,” the Deer Coffee Filter employs a more advanced manufacturing process.

In-Depth Analysis: Traditional virgin wood pulp filter paper does indeed have noticeable lignin residue, producing a cardboard-like taste. However, Deer’s long-fiber, high-purity process involves multiple enzyme bleaching and ion exchange treatments, resulting in extremely low sensory residue.

Conclusion: * In competition-level brewing where extreme purity is paramount, we still recommend wetting the filter paper to remove trace amounts of dust;

In everyday, fast-paced brewing, the excellent physical properties of Deer filter paper allow you to omit the wetting step (provided the filter cup is preheated) without detecting any noticeable papery taste.

| Scene | Is moisturizing recommended | Core reason |

| High heat capacity filter cup (ceramic/glass) | Strongly recommended | Compensates for heat loss and stabilizes extraction water temperature |

| Low heat capacity filter cup (resin/PCTG) | Optional | Primarily used to eliminate paper dust interference, with minimal impact on temperature |

| Light roast coffee beans | Recommended | Shallow drying is temperature-sensitive and requires preheating to maintain a high extraction temperature. |

At Deer Coffee Filter, we believe that wetting the filter paper is not just for cleaning, but also for the final shaping of its physical structure. Different filter paper shapes require completely different wetting focuses:

- V60 Conical Series: Optimizing the “Exhaust Channel”

The essence of the V60 filter paper lies in the flow rate control provided by its 60° angle.

Why Wet: V60 filter cups typically have tall, spiral ribs. Wetting allows the filter paper to precisely “hang” along the edge of the ribs, rather than collapsing into the grooves.

In-depth Details: Wet Deer conical filter paper creates tiny vertical air channels between itself and the filter cup. This helps to quickly expel carbon dioxide during the blooming stage, preventing gas from obstructing water flow and ensuring a vertically downward extraction path.

Operating Suggestion: Start from the center and quickly spiral outwards. Note: Do not press the filter paper with your hand after wetting, as this may damage the inter-fiber spaces.

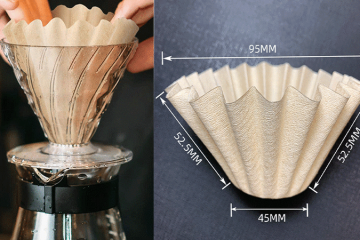

- Fan-Shaped/Trapezoidal Series: Preventing the “Edge Channeling Effect”

Fan-shaped filter papers are typically used in extraction methods combining immersion and dripping, and they have more folds at the bottom.

Why Wet? When dry, fan-shaped filter papers tend to have gaps at the bottom corners. If not wetted with hot water to ensure a smooth fit, the hot water will flow through the gaps between the filter paper and the filter cup wall (bypassing), resulting in a weak and astringent coffee.

In-Depth Details: When wetting Deer fan-shaped filter papers, water pressure helps the “double-stitched” structure at the bottom of the filter paper perfectly adhere to the bottom of the filter cup, ensuring that every drop of water passes through the coffee bed, improving the evenness of extraction.

Operating Suggestions: Focus on wetting the stitched areas at the bottom of the filter paper, ensuring the bottom is fully unfolded and free of air bubbles.

Material-Specific Analysis: Thermodynamic Properties of Deer Filter Paper

Physical Feedback of Different Deer Filter Paper Materials Upon Wetting:

| Filter paper series | Fiber properties | Changes after wetting | Brand Recommendations |

| Oxygen Bleached | High-purity long fibers | Instant penetration, no paper smell shifts | The focus is on preheating the filter cup, not on washing away the paper smell. |

| Unbleached | Natural wood fiber | The fiber swells significantly when it absorbs water. | It must be thoroughly moistened (approximately 50-100ml of hot water) to activate the fiber’s flexibility and wash away the natural woody odor. |

Final Advice for Users

If you are using Deer Pro High-flow ultra-thin coffee filters, please be gentle when wetting them due to their extremely high permeability. Excessive heat and high flow rates can sometimes cause the ultra-fine fibers to shrink prematurely. We recommend using hot water at 85°C – 90°C for optimal fiber retention.

0 Comments