In the fields of coffee brewing and laboratory filtration, the quality of filter paper directly affects the purity and safety of the final product.

I. Can Expired Filter Paper Still Be Used?

Expired filter paper not only affects flavor but also indicates a decline in physical properties.

While filter paper doesn’t have a strict “spoilage” date like food, its physicochemical properties degrade with environmental changes.

- Fiber Toughness and Structural Integrity

Filter paper is primarily composed of plant fibers. Over time, fluctuations in humidity cause repeated moisture absorption and dehydration of the fibers, leading to fiber embrittlement.

Quantitative Indicator: Filter paper stored for more than 3 years experiences an average decrease in wet tensile strength of 15%-20%. During brewing, this significantly increases the risk of filter paper breakage and filter residue contaminating the liquid.

- Pore Size Shift

Prolonged pressure or moisture absorption causes deformation of the interwoven gaps between fibers. Impact: The originally uniform 5-10 μm pore size may enlarge due to loose fibers, leading to decreased filtration accuracy; or it may become clogged due to adsorbed dust particles, reducing the flow rate by approximately 30%, resulting in over-extraction. - Chemical Residues and Microbial Risks

Odor Absorption: Paper has extremely strong porosity and adsorption properties. Even in a sealed environment, residual lignin in the paper may slowly oxidize, producing a “paper smell.”

Fungal Toxins: If the storage environment humidity exceeds 60%, invisible mold spores may grow in the fiber gaps. Conclusion: Filter paper stored for more than 2 years without moisture protection is not recommended for food filtration.

II. Are there reusable environmentally friendly filter papers?

The cost-benefit trade-off of reuse

However, when looking for filter paper alternatives, one cannot only consider “waste reduction” but must also consider its environmental footprint throughout its entire life cycle.

- Comparison table of common reusable filter media:

| Filter media type | Main advantages | Potential disadvantages | Maintenance Costs (LCA) |

| Stainless steel filter screen | Zero consumables, preserves coffee oils | High pass rate for fine powder (approximately 15%) | It needs to be rinsed with hot water and detergent. |

| flannel filter cloth | Rich and smooth texture, high filtration accuracy | Easy to breed bacteria, grease residue | Requires long-term refrigeration and soaking, and periodic boiling. |

| Ceramic/Mineral Filter Cups | Water quality regulation, far-infrared effect | Easily clogged, extremely difficult to clean | Residue needs to be periodically removed by open flame calcination. |

- Environmental Payback Period

According to life cycle assessment models, the energy and carbon emissions consumed in producing one 304 stainless steel filter screen are roughly equivalent to producing 150-200 sheets of wood pulp filter paper.

In other words, only when you intend to use a reusable filter media more than 200 times consecutively does its environmental value truly surpass that of disposable filter paper.

III. Recommendations

For expired filter paper: If the filter paper is yellowed, feels brittle, or has a noticeable musty smell, please discard it immediately. Recycling for non-food applications (such as cleaning oil stains) is a better option.

For environmentally friendly options:

- For high-frequency users: High-quality stainless steel filter screens are recommended, combined with ultrasonic cleaning.

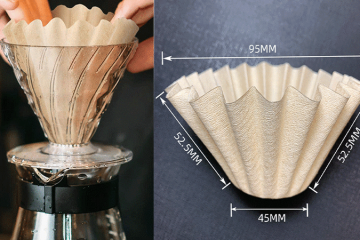

For infrequent users: We recommend ordering deer disposable coffee filters and composting them after use, which is more environmentally friendly than creating a metal filter that sits idle for a long time.

0 Comments