Coffee filters is a cellulose-based material designed for solid-liquid separation during brewing. It works through surface capture, depth filtration, and selective adsorption, each of which shapes the coffee’s final taste and chemistry.

Material and Construction

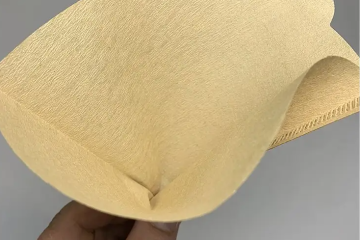

The paper consists mainly of α-cellulose from wood, bamboo, or cotton pulp. A wet-forming process creates a porous network with pores between 10–20 microns. Gram weight and thickness then determine flow speed and durability.

Bleaching and Surface Treatment

Manufacturers often bleach paper with hydrogen peroxide or ozone. This reduces lignin and prevents unwanted odors. Unbleached paper keeps its natural lignin but may release phenols when wet. Therefore, always pre-rinse unbleached filters to avoid affecting flavor.

How It Functions

Separation and Flow Control

The paper first traps coffee particles larger than 50 microns. It also manages water resistance, promoting even saturation. Additionally, a fine coffee-powder layer builds up on the surface, forming a secondary filter for greater clarity.

Selective Adsorption

Cellulose fibers bind to oil molecules like cafestol through hydrogen bonds. This greatly lowers oil content. The process also captures certain aromatic compounds, altering the coffee’s fragrance profile.

Effects on Coffee Composition

Using coffee filters removes 80–90% of coffee oils, lightening the body. It also filters out diterpenes, which may influence cholesterol. Finally, it clears particles above 15 microns, giving a bright, sediment-free brew.

Practical Recommendation

For a cleaner, smoother cup, paper filters are ideal. Always rinse them before use—especially unbleached versions—to ensure no paper taste remains.

0 Comments