The coffee basket filter is a precision-engineered cellulose-based separation medium integral to the pour-over and automated drip coffee brewing processes. Its primary functions are the mechanical retention of particulate coffee grounds and the selective adsorption of hydrophobic compounds, thereby modulating the chemical and sensory profile of the final brew.

- Manufacturing Process: From Pulp to Precision Filter

Commercial paper coffee filters are manufactured via a continuous wet-lay process optimized for controlled porosity and biocompatibility.

1.1 Raw Material Preparation

Filters are predominantly fabricated from virgin wood pulp (typically Betula spp. or Pinus spp.), chosen for its long, flexible cellulose fibers. The pulp undergoes kraft or sulfite processing to delignify the wood, yielding a high-alpha cellulose content (>90%). This pulp is then subjected to elemental chlorine-free (ECF) or totally chlorine-free (TCF) bleaching using hydrogen peroxide (H₂O₂) or ozone (O₃) to achieve target brightness (85-92 ISO) and to eliminate residual lignins that impart off-flavors.

1.2 Sheet Formation and Engineering

The bleached pulp is diluted to a consistency of ~0.5% in water and formed into a continuous sheet on a Fourdrinier wire. Key engineering parameters are controlled at this stage:

Basis Weight: Ranges from 25-35 g/m². Thicker sheets (e.g., 35 g/m²) provide greater wet strength and retention.

Porosity (Gurley Method): Calibrated to 15-25 seconds for 100 mL of air, balancing flow rate with fines retention.

Wet Strength Additives: Food-grade polyamide-epichlorohydrin or urea-formaldehyde resins (at <0.1% wt.) are added to the furnish to maintain integrity when saturated at 90-96°C.

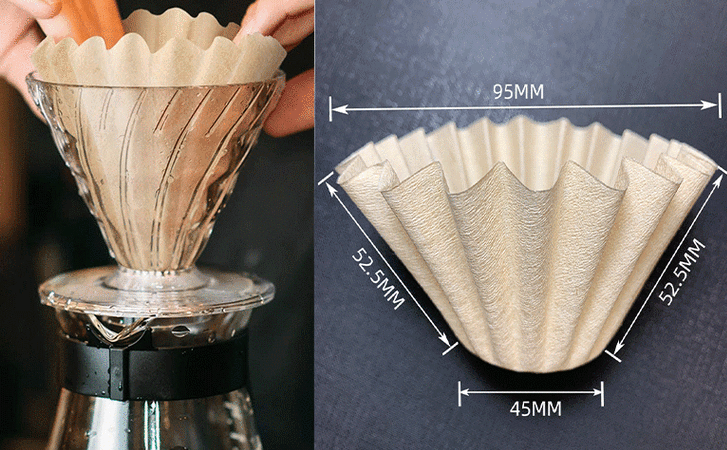

1.3 Converting and Finishing

The dried parent roll is stamped using heated, matched-metal dies. The characteristic fluted or pleated geometry serves a dual purpose: it increases surface area by approximately 40% and provides radial rigidity to prevent collapse against the brew basket walls. The filters are then packaged in low-O₂ barrier packaging to prevent odor adsorption and microbial growth.

Unbleached (natural) filters omit the peroxide bleaching stage, retaining more lignin and hemicellulose. This results in a lower wet-strength and a basis weight approximately 10-15% higher to achieve comparable performance, accounting for their darker color and subtly higher adsorption capacity for certain organic compounds.

- Function: Physicochemical Filtration Mechanisms

The filter operates via Mechanical Sieving (Size Exclusion) or Adsorptive Filtration (Selective Removal)

primary mechanisms during the coffee brewing process, which is fundamentally a solid-liquid extraction.

coffee basket filters produces a brew with lower total dissolved solids (TDS) from lipids and suspended colloids, but higher relative concentration of hydrophilic acids, sugars, and caffeine. The sensory result is a beverage with greater perceived clarity, acidity, and flavor differentiation, as opposed to the increased viscosity, turbidity, and “heavy” mouthfeel characteristic of unfiltered methods.

- Application Protocol for Optimized Extraction

Proper filter use is critical for replicable extraction yield and sensory outcomes, governed by the principles of the SCA (Specialty Coffee Association) Golden Cup standard.

3.1 Preparation and Pre-wetting

Sizing: Must match the brew basket geometry, Mismatch leads to channeling or bypass.

Rinsing: Saturating the filter with hot water (92-96°C) prior to adding coffee grounds serves three functions:

Thermal Management: Brings the brew chamber to target temperature, preventing heat loss at the critical onset of extraction.

Adhesion: Allows the filter to conform to the basket walls, eliminating a potential pathway for water to bypass the coffee bed (“bypass flow”).

Neutralization: Removes soluble cellulose residues and any potential paper-derived volatile organic compounds (VOCs), which is particularly recommended for unbleached filters.

The paper coffee basket filter is a consumable, engineered component whose material properties—cellulose purity, basis weight, porosity, and geometry—directly govern the physicochemical.

2 Comments

Porn Tude · 01/27/2026 at 20:15

How are you?

a1009113800 · 01/28/2026 at 14:29

fin thx