Cone coffee filters are the core components of drip coffee systems, their function extending far beyond simple solid-liquid separation.

The filter paper used in cone coffee filters is mainly made of three materials, each with its own characteristics:

- Virgin wood pulp filter paper: The most common type, usually bleached. Modern bleaching processes mostly use oxygen bleaching, so there’s no need to worry about chemical residues. This type of filter paper has almost no paper taste and best presents the flavor characteristics of the coffee itself.

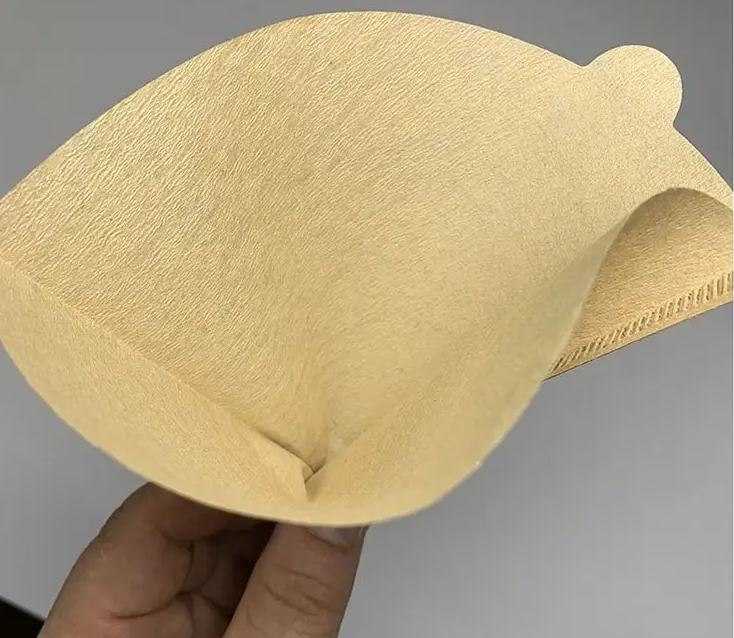

- Unbleached filter paper: Presents a natural light brown color; some consumers prefer its “natural feel.” However, it may have a slight cardboard taste initially, and rinsing with hot water is usually recommended.

- Special material filter paper: Such as hemp fiber blend filter paper, with slightly higher porosity, allowing more oils to pass through. The taste is closer to that of a metal filter, but its cleanliness is still superior.

The working principle of cone coffee filters is based on a clever combination of multiple scientific principles:

- Filtration mechanism: The micropores of the filter paper are approximately 20 micrometers in diameter, small enough to trap coffee grounds (typically 500-600 micrometers in diameter) while allowing water molecules and dissolved flavor compounds to pass freely. This selective permeation is key to the clear taste of coffee.

Adsorption: The surface of the filter paper fibers carries a slight negative charge, allowing them to adsorb some of the acidic substances and cafe stols from the coffee oils. This chemical process effectively reduces the bitterness and oiliness of the coffee, which is a major reason for the flavor difference between filter paper coffee and French press coffee.

The hydrodynamics of the conical design: The conical structure creates a unique extraction environment. As water flows downwards through the coffee grounds, the path gradually narrows, naturally creating an extraction gradient—stronger extraction at the top and weaker at the bottom, eventually reaching equilibrium in the cup and avoiding the bitterness caused by over-extraction.

Temperature retention: Paper filter cups have better heat retention than metal filters, maintaining a more stable extraction temperature, which is one of the key factors in the complete extraction of coffee flavor compounds.

Customizing conical filter paper requires consideration of the following key factors:

Material Selection:

Porosity Testing: Before customization, request the supplier to provide samples with different porosities for blind testing. Even slight differences can significantly alter the extraction rate.

Safety Verification: Ensure the filter paper meets food contact material standards and is free of fluorescent agents, heavy metals, and other harmful substances.

Wet Strength Testing: High-quality filter paper should maintain its integrity even under saturation to prevent breakage during extraction.

Structural Parameters:

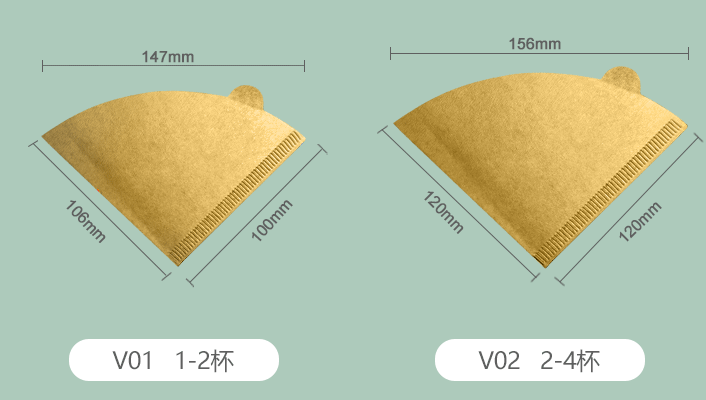

Cone Angle Accuracy: A common 60-degree cone angle is suitable for standard filter cups such as the Hario V60. When customizing, the exact angle of the existing filter cup must be measured.

Seam Design: Ultrasonic bonding of seams is safer than glue bonding, eliminating the risk of chemical migration.

Bottom Shape: Flat bottom or pointed bottom? This will affect water flow rate and final extraction time.

Functional Enhancements:

- Scale Markings: Consider printing water volume reference lines to assist in hand-drip process control.

- Pre-crease Design: Optimize the fit after folding, reducing gaps between the filter and the filter cup.

- Environmental Considerations: Utilize renewable materials such as bamboo pulp and bagasse, and ensure sustainability in the production process.

Customization Practice Steps:

- Determine Needs: Define the usage scenario (home/commercial), compatible filter cup models, and daily usage.

- Sample Testing: Test at least three batches of samples: for new filter paper testing, comparison with competitors, and long-term storage testing.

- Production Supervision: Confirm that the production environment meets food safety standards; conduct full quality testing on the first batch of products.

- Usage Optimization: Fine-tune the grind size and brewing parameters according to the characteristics of the customized filter paper. New filter paper typically requires a slightly coarser grind to compensate for different flow rates.

Note: Even the highest quality filter paper can affect coffee quality if used improperly.

- Necessity of Pre-rinsing: Thoroughly rinsing the filter paper with 92°C hot water not only removes potential paper flavor but also preheats the filter cup, making the extraction temperature more stable. Studies show that a fully preheated filter cup can increase the initial extraction temperature by 3-5°C. Folding Technique: Fold along the seam to ensure a tight seal between the filter paper and the filter cup. Even tiny gaps can cause short-circuiting of the water flow, disrupting even extraction.

Disposal: Used filter paper makes excellent compost. Coffee grounds are high in nitrogen, creating an ideal carbon-to-nitrogen ratio with the carbon in the filter paper, allowing it to be converted into high-quality fertilizer in approximately 6-8 weeks.

0 Comments