Coffee filter paper is far more than a simple consumable. In fact, its early 20th-century invention was a fundamental innovation with wide-reaching impact. By offering efficient, cheap, and consistent filtration, it set a new physicochemical standard for modern brewing. More importantly, it created a standardized, scalable system. Consequently, this system optimized the final product’s quality while simultaneously restructuring production, commerce, and consumption. Therefore, filter paper is rightly considered a crucial platform technology.

Technical Core: A Qualitative Leap in Separation

The core innovation lies in separation efficiency. Previously, methods like metal mesh or cloth had larger, irregular pores. As a result, they failed to stop micron-sized particles and colloids, which left insoluble solids and oils in the brew, ultimately harming its stability and taste.

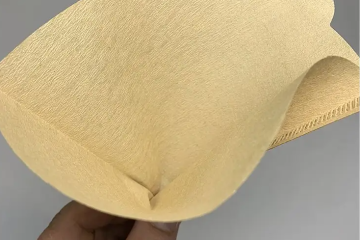

Specialized cellulose filter paper changed this through key features:

Controlled porosity: It traps particles over 15-20 microns, thereby creating a clear liquid.

Selective adsorption: Furthermore, its cellulose material partially holds coffee oils, reducing turbidity and astringency.

Consistency and inertness: Importantly, each new paper provides a clean, residue-free environment, ensuring reproducible results.

This breakthrough made “clarity” a new coffee standard. Specifically, it removed past negative flavors from poor filtration and allowed the coffee’s acids, sugars, and aromas to shine through distinctly. In this way, it provided the essential foundation for the later specialty coffee movement.

Industrial Impact: The Creation of a Standardized System

Beyond the kitchen, filter paper’s influence reshaped industry systems and profits.

Standardized Equipment Interfaces: As a middle medium, filter paper required precisely matching equipment. Consequently, this led to standard filter cup systems like the conical V60 or fan-shaped Kalita Wave. These designs control water flow and temperature, thus turning extraction from vague art into quantifiable science.

The “Razor and Blade” Consumable Model: For example, inventor Melitta’s company perfected this. Adopting a filter cup system locks consumers into buying its specific paper, thereby creating a high-retention, high-margin consumable market.

Extending the Supply Chain: Additionally, mass production spurred a specialized niche industry, from wood pulp processing to packaging.

The Prerequisite for Third Wave Coffee

The “Third Wave” movement seeks to trace and precisely express coffee’s agricultural flavors. Notably, pour-over brewing with filter paper became its icon for several key reasons:

Gentler, Flavor-Focused Extraction: Compared to espresso’s high pressure and heat, pour-over uses lower temperature and atmospheric pressure. Hence, it minimizes bitter over-extraction, better showcasing delicate aromas and acids in light roasts.

Unmatched Clarity and Isolation: The resulting oil-free, clear brew has less complexity than French press coffee. However, its advantage is flavor “separation” and “clarity.” As a result, tasters can more accurately identify specific notes like citrus or jasmine.

A Tool for Education and Control: Moreover, every pour-over variable affects the result. Therefore, it serves as an excellent tool for teaching extraction science.

Conclusion: A Subtle Revolution in Hygiene and Standardization

Finally, the single-use nature of coffee filter paper completely eliminated the problems of microbial growth and oil oxidation from reusable cloth filters. This established a new, critical standard for hygiene in home beverage preparation, representing the final, subtle yet profound improvement delivered by this foundational technology.

0 Comments