Coffee filter paper is a crucial medium for liquid-solid separation. Its properties directly determine 12-18% of the final cup’s quality. Thus, choosing the right filter paper matters significantly.

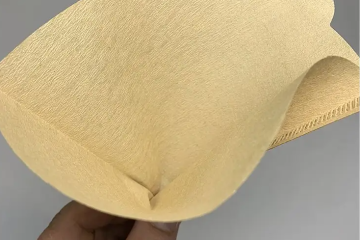

A good filter paper shows even texture under light. It also holds its structure when wet. This durability is key for consistent performance.

In essence, this paper controls extraction kinetics precisely. It separates substances through physical and chemical means. This process changes water flow and extraction timing. Ultimately, it reshapes the sensory experience, affecting 25-30% of the flavor.

Key membrane parameters include pore size distribution. Quality paper has a layered pore structure: 5-8 μm on the surface, and 10-15 μm at the bottom. This design filters progressively. First, it catches large particles (>15 μm). Then, it traps finer grounds (8-15 μm). Finally, it holds back oily cafestol clusters.

Modern bleaching also modifies the fibers. Processes like ECF or TCF oxidize cellulose. This creates a carboxyl density of 12-18 μmol/g. It also yields a zeta potential of -35 to -45 mV at pH 6.8. As a result, the paper attracts positive colloids. This action reduces turbidity below 2.5 NTU.

Proper pretreatment optimizes results. Use 92±2°C water to activate the fibers. The water volume should be 12-15 times the paper’s dry weight. Then, wait 45–60 seconds. This allows full fiber expansion for best performance.

0 Comments